System Rebuilds

A look at our system rebuild process

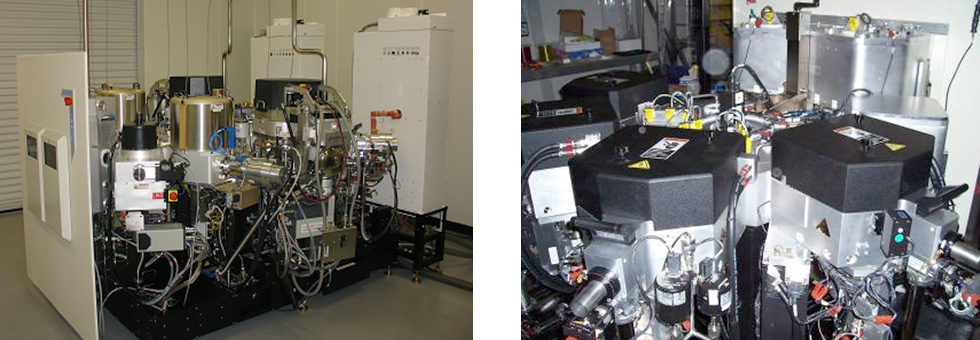

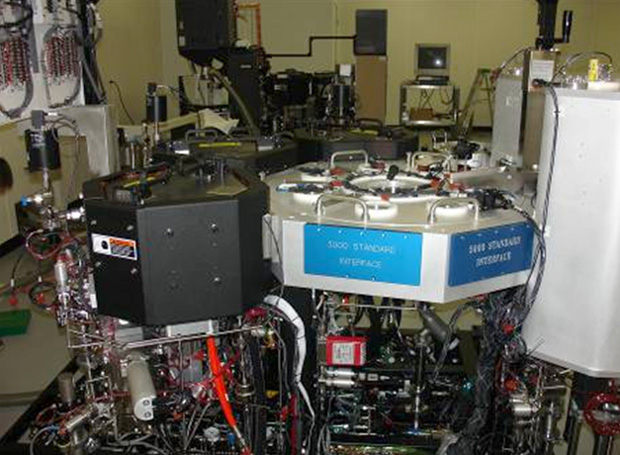

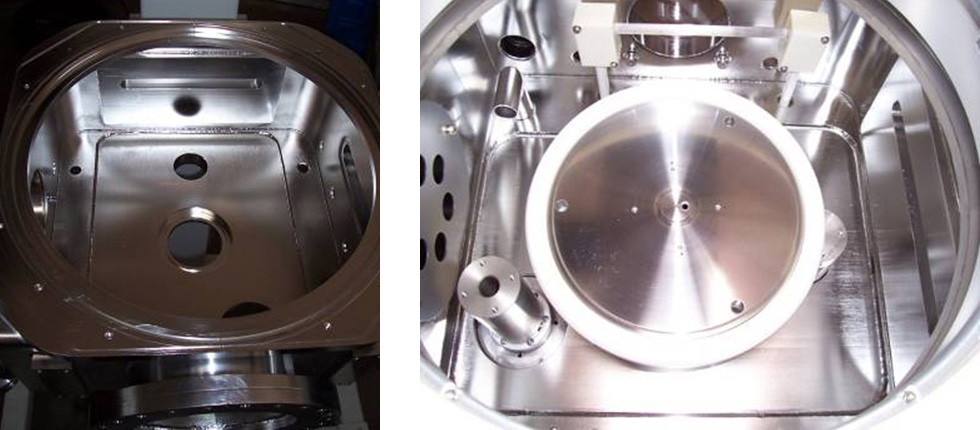

During the rebuild process, all steps are tracked using project management software to ensure that your product is properly built, thoroughly tested and delivered to you on schedule. Below is an example project that demonstrates our system rebuild process and principles.Monolith and mainframe are stripped and cleaned to prevent contamination issues.

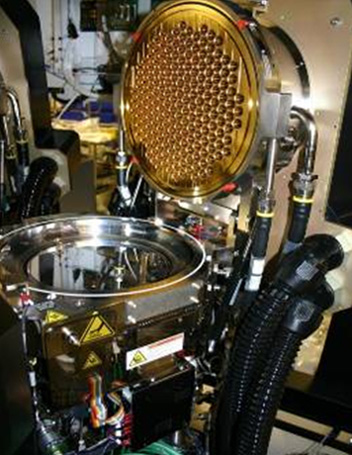

New powder-coat during rebuild. | | Forelines and valves are rebuilt or new from OEM. |

|  |

Turbos are rebuilt with | | Lamps are replaced with OEM |

|  |

Gas panel rebuild with new valves, new tubing, and new or rebuilt MFCs.

(All parts come with warranty.)

Current safety upgrades are completed during refurbishment.

Current safety upgrades are completed during refurbishment.

After the rebuild, we test the system through Applied Materials Tier I at our facility.